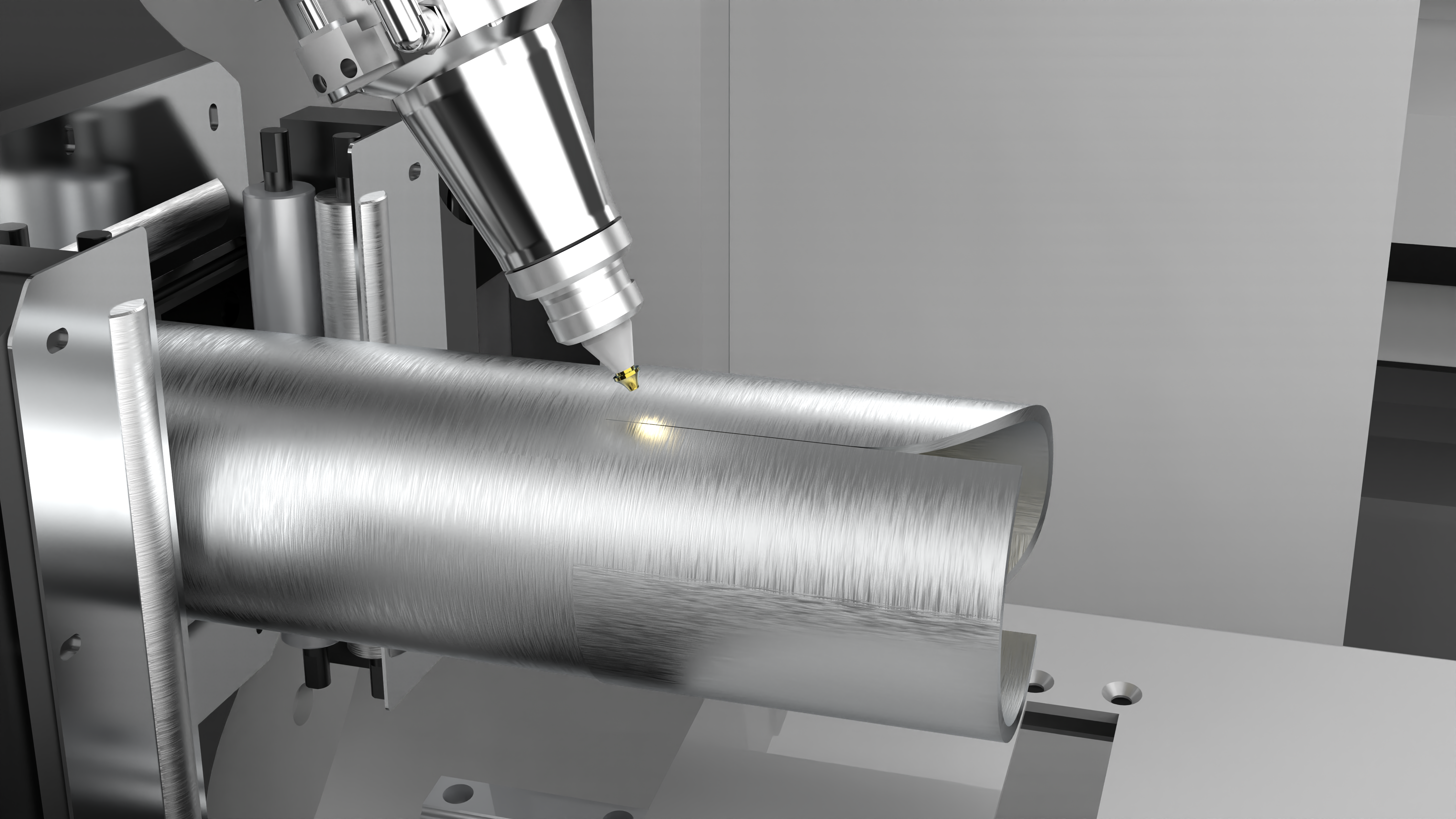

Modern manufacturing is all about efficiency, especially when it comes to pipe fabrication. With the introduction of Tube laser cutting machines, operational efficiency, precision, and productivity have significantly increased, and these machines might just be the new revolution in the industry. In this article, we will cover the numerous ways in which these machines are evolving within the pipe fabrication sector and how they are resolving the gaps found within the manufacturers' processes while managing to keep costs low.How Do Tube Laser Cutting Machines Work?These specialized machines employ advanced laser technology to cut through different materials with high precision accuracy and power. With the ability to cut through metals and plastics, the machines allow for intricate designs and detailed precision that would be very difficult to achieve with standard techniques. The technology's capability to make complex cuts without bulky tooling also makes it quicker and significantly reduces material waste, hence, being more suitable for the environment.Improving Accuracy While Lessening WasteOne of the greatest attributes of tube laser cutting machinery is the advanced level of accuracy it can achieve. Thanks to its CNC systems, advanced computer numerical control systems, these machines cut with utmost proficiency to ensure each piece is sliced according to the exact specifications of the customer. This accurately achieved precision cuts made on tube laser cutting machines minimizes chances of error, hence eliminating costs incurred from rework and material wastage. Increasing Efficiency In Production TimesSpeed is also incredibly important in the pipe fabrication industry and tube laser cutting machines are second to none when it comes to speeding up production. Automation of the cutting process means less manual work, and proper tube laser cutting machines eliminate the possibility of human errors. Out of all cutting techniques, traditional methods require the most number of processes to achieve the intended cut. Each of these steps extend the timeline for production, hence incurring more expenses to the manufacturer; meanwhile tube laser cutting machines shorten this timeline by speeding up the process, increasing productivity to meet tight deadlines and overall customer satisfaction.Scope in Material HandlingFrom the very start, the business of tube laser cutting machines had advantages because they streamline the cutting of different materials like stainless steel, aluminum, and carbon steel. This means that manufacturers can change their products to appeal to more industries, like the automotive and construction industries.Moore’s Law Applications on Industry 4.0Industry 4.0 has marked the beginning of smart manufacturing which is where tube laser cutting machines come into this picture. These machines can be employed with the other smart technologies like IoT devices and data analytic tools which allows the establishment of a connected manufacturing space. This allows one to monitor real time production data and even predict maintenance and repairs on damaged parts enhancing decision making. Conclusion: The Future of Pipe FabricationWith laser pipe cutting machines, components like pipes can be fabricated or assembled more effectively, allowing for enhanced operational speed and efficiency. As technology improves further, manufacturers will expect these machines to perform even more than what is currently achievable.