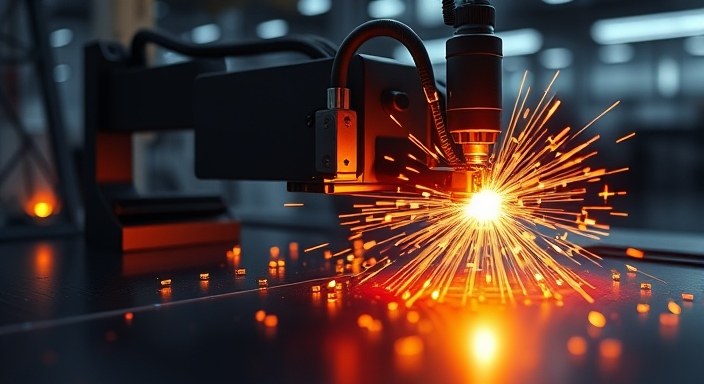

Today, there is no denying the fact that CNC laser cutting machines have become essential for modern factories and hence are being infused into the manufacturing ecosystem. The advantages these machines come with include increased precision, improved productivity, enhanced efficiency, and greater cost savings.

The Accuracy in Production and its Significance

Accuracy is important in any activity and look at how pertinent it is in manufacturing, looking especially at the aerospace, automotive, and electronics industries. CNC laser cutting allows manufacturers to process volumetric parts with high accuracy all the time. Unlike other methods of cutting, which can be prone to mistakes, the use of CNC lasers ensures that every cutting tool is guided by design drawings stored on a computer.

Enhancing Efficiency And Rate Of Completion

In these highly modernized factories, there is always an effort to find a balance between efficiency and reducing production rates. Conventional methods of cutting highly differ from CNC laser cutting. The speed at which these CNC machines operate significantly fastens the production rate leading to more customers being satisfied in a quicker manner. Furthermore, these machines can cut materials consistently, which maximizes the production intake.

Wide Application Across Borders

CNC Laser cutting has a wide range of applications especially with its innovative cutting mechanisms, which do not limit its use to one industry. Using these machines enables the cutting of different types of materials: metals, plastics, wood, and even composites, which helps everyone in a different industry. The automotive sector uses CNC machines for complex components, while in the retail industry, its use extends to signage and decorative pieces. This increases the product range and allows businesses to fulfill the needs of different people without having to spend money on numerous special machines.

*Cost Split Up and Material Reduction

Purchasing a CNC laser cutting machine is a cost-friendly option in the long run when comparing to traditional methods. Most forms of cutting creates wastage, but laser cutting works wonders with minimal wastage of materials and resources because it is tremendously efficient. Additionally, the use of CNC machines further reduces the requirement of manual labor which in turn saves a lot of money in the long run due to the fact that CNC machines can operate with little to no supervision aid. Eventually, after some time, the investment into the CNC technology laser cutting starts providing positive returns in terms of operational savings and profit returns.

Upcoming Developments in CNC Laser Carving Technologies

When evolution occurs within the field of technology as a whole, it translates to the technology of CNC laser carving as well. Fiber laser technology, for instance, is very popular these days because it’s over all efficiency is groundbreaking, all while being able to effortlessly cut sturdier materials. Moreover, the field of automation and artificial intelligence is progressing at a tremendous pace, assisting in transforming manufacturing processes to be much smarter, where CNC laser sculpting machines can work on their own without needing energy or assistance and can adjust to the needs of production.

To sum up, CNC laser cutting machines are a must-have investment for cutting-edge factories today because of their precision, effectiveness, flexibility and economy. With the present trends in the industry, adopting such sophisticated tools will definitely be needed in order to remain relevant and address the needs of the moving target market. Investing on CNC laser cutting will ensure that manufacturers meet the demands posed by the future while offering impeccable products to their clients.