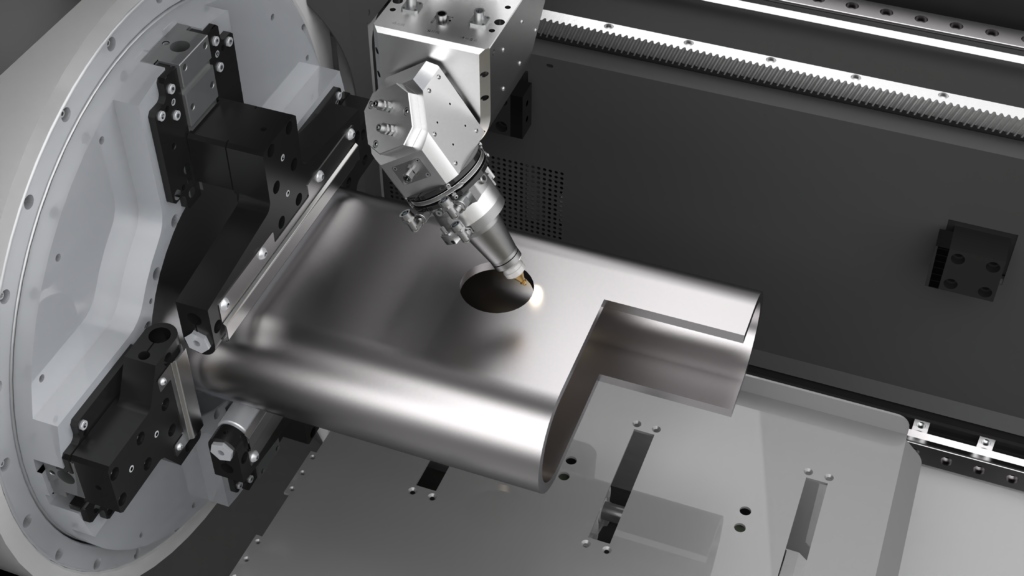

Modern manufacturing and fabrication has made the selections of machines and tools very pivotal for the productivity and precision. One of the crucial machines in this category is the pipe laser cutting machine. The objective of this post is to give you insights on how to select the right pipe laser cutting machine.What Is Pipe Laser Cutting Machine?Pipe laser cutting construction is a manufacturing procedure that employs a laser beam to cut pipe materials accurately. It makes use of a high-powered laser beam that vaporizes the targeted material, and is ideal for precision cutting of complex parts. These machines have found the most applications in construction, automotive, and even aerospace industries where precision and high productivity goes hand in hand. The first step is learning what matters to these machines in order to make a better decision.Key Features To ConsiderThere are some features which are common and need to be considered when selecting pipe laser cutting machines.

- Laser Power: The cutting speed and thickness of the material dictatess the power of a laser. Superior power lasers cut through thick materials faster , but are surely expensive.

- Cutting Speed: It is important to analyze the machine's working speed because it affects productivity. A more rapid cutting speed can lower the costs and increase how productive your production line is.

- Material Compatibility: Machines are made differently to cut different materials such as steel, aluminum, alloys, etc. Make sure that the one you use is suitable for the materials you intend to use.

- Automation Features: Automation is one of the most sought features of modern machines because it markedly increases efficiency. These include automatic loading and unloading devices and sophisticated cut programming software that saves time and labor.

- Maintenance and Support: Do a cost-benefit analysis with regards to the maintenance support the manufacturer provides. A good machine with excellent after sales service will save you time and money.

Cost ConsiderationsWith laser cutting machines that use pipes, as diverse as their manufacturers, so too are the expenses. Be prudent enough to create a budget that works for you business-wise, while still being affable when it comes to investing returns. You tend to save a lot more money with cheaper machinery, but it hampers efficiency in the long run, leading to higher upkeep expenses. On the other side of the spectrum, high-quality systems pack the punch for superior performance and longevity at the low-end expense band.Evaluating Your Specific NeedsEvery business has bespoke needs, be it production amounts, complexity when cutting, or the kinds of materials they need. A business would need a deep analysis of their requirements to truly such magic – holistic assessement of needs are vital. Take into accounts details such as:

- Your anticipated workload.

- Kind of work you do.

- The skill set of your team, especially related to laser technology.

If you get a better understanding of these pointers, you can get a great head start in finding a machine which specifically works for your business.Industry Trends and Future OutlookThe pipe laser cutting business is profoundly changing, this can be attributed to the evolving technology over the years. The inclusion of cutting-edge technology such as AI and machine learning into cutting machines is boosting the efficiency of their operations. Furthermore, the need for sustainability encourages manufacturers to produce machines with lower energy consumption and waste generation. Being familiar with these trends will ensure that you make wise decisions with regard to your equipment purchases and position your company appropriately in a competitive market.