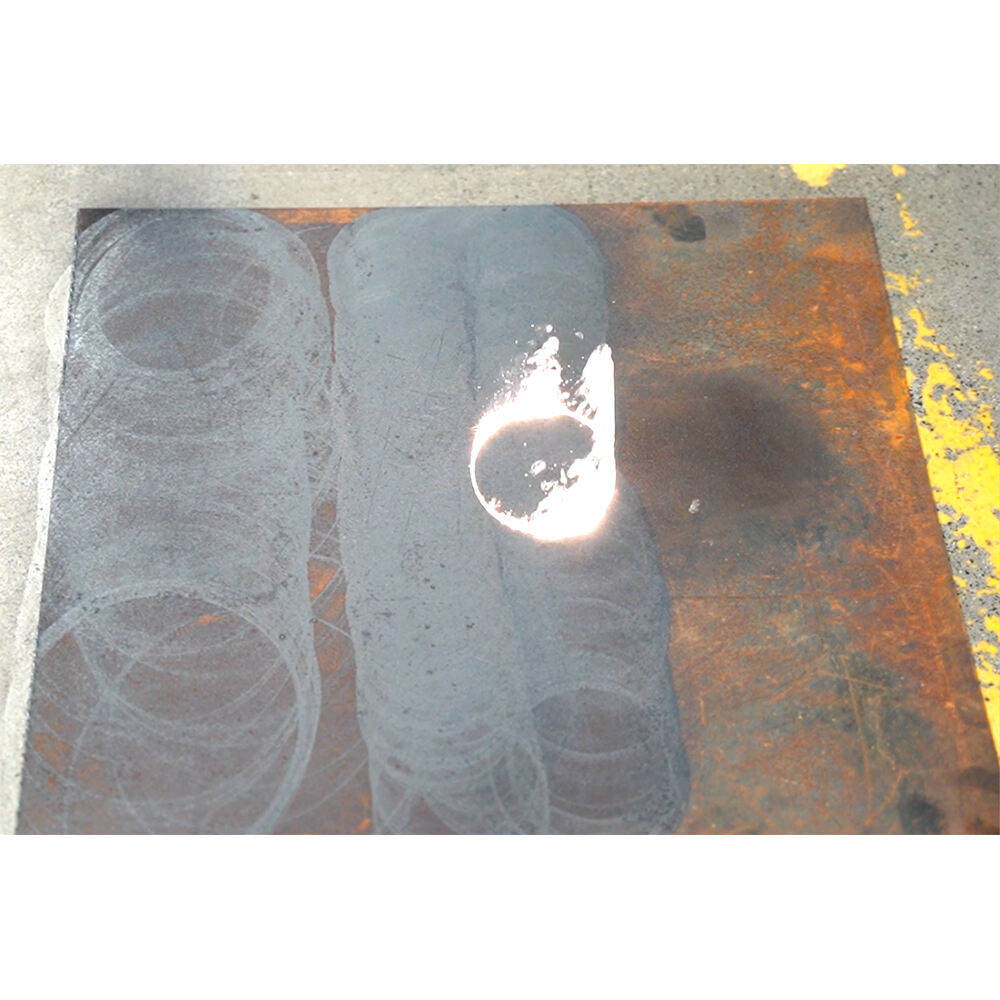

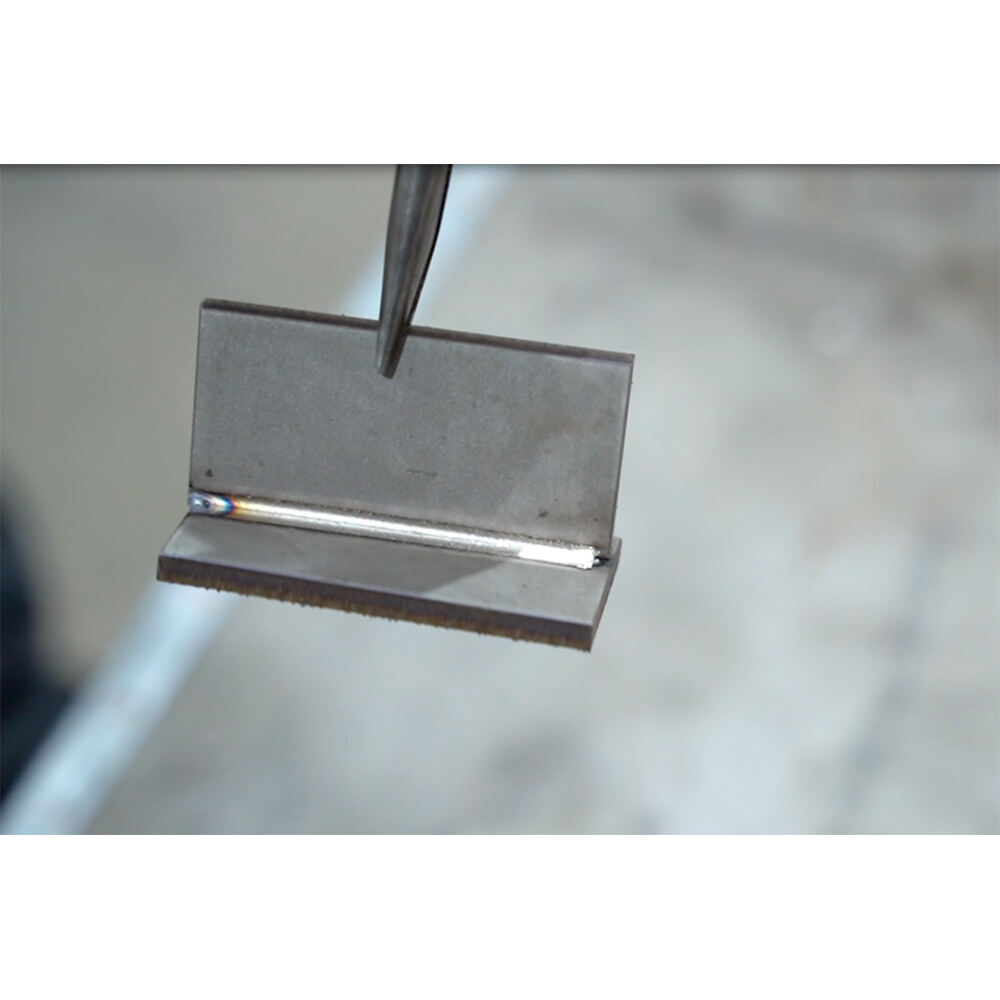

The debate of Laser welding vs TIG welding is a significant one, especially when choosing between quality and efficiency. With a greater degree of skill required as well as the amounts of time that it consumes, TIG welding is known for versatility with multiple types of metals. Laser welding, on the other hand, requires the use of a tightly focused beam of light to make welds, this greatly optimizes efficiency while also reducing the level of thermal distortion to welds. This trade-off makes it optimal for applications that require high levels of precision. With advanced laser technology, RT Laser’s guarantees output according to your individual project requirements whether big or small.